Traditional company relies on innovation

The family company DESOI GmbH shows how the balancing act between tradition and innovation succeeds. We spoke to long-standing application engineer Bernd Kress about how w.i.l.m.a. made the switch from mechanics to electronics possible and how other companies can also succeeded in taking this step.

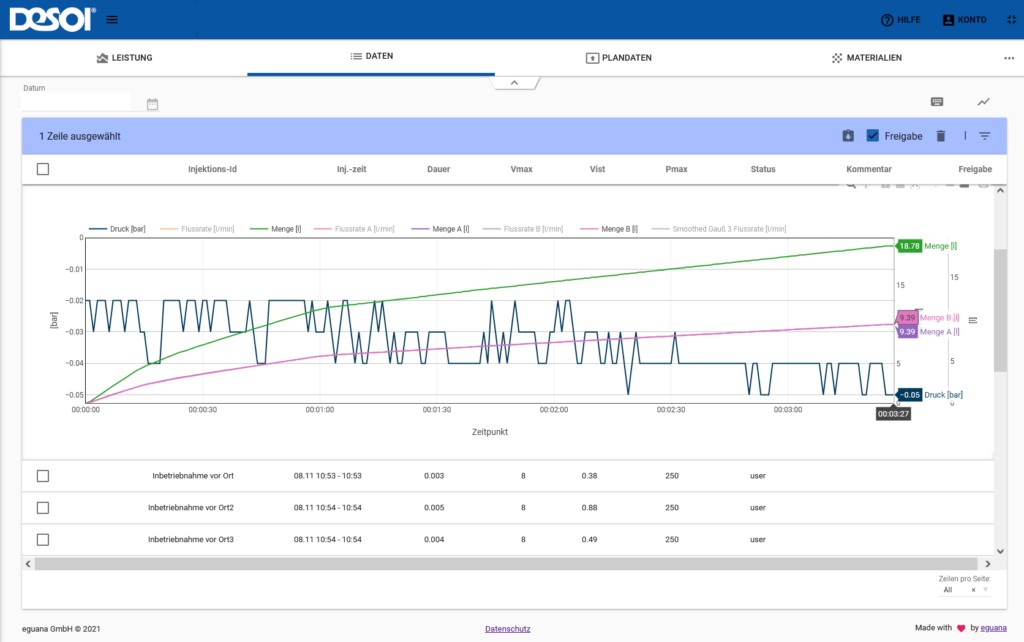

At eguana we live the change. In the spirit of Charles Darwin, we also believe that only those who keep up with the times and adapt in good time will make progress. So when DESOI approached us with an idea to modernize special civil engineering, we were thrilled. The result of our collaboration is w.i.l.m.a., the “wireless injection logging monitoring assistant”, an electronic device that records all data occuring during an injection.

*****

Traditionally, data generated during an injection is collected and either documented on paper or transferred to a local computer. With w.i.l.m.a., the data flow no longer ends at the device, but is transmitted wirelessly to eguana SCALES. All data is of course protected by the latest technologies and processed and managed exclusively on servers in Germany in order to guarantee absolute data protection. On the digital platform, data can be viewed, analyzed, handed over to clients and of course also printed out by the project participants from anywhere. “I have a proper list, a clean basis for accounting and proof that I did what I was supposed to do,” for example whether the pressure, quantity or mixing ratios were complied with, emphasizes Kress.

Until then, DESOI’s product range was very mechanical, from packers, hoses and cylinders to mixing and pumping equipment and anchoring systems. w.i.l.m.a. on the other hand, is electronic/digital. The trigger for dealing in this direction came from the customer side. “We specialize in listening to our customers and realizing what the customer wants,” says Kress. So when a material manufacturer expressed the desire for a control device for injections, DESOI didn’t hesitate long.

bring staff on board

Since DESOI is an owner-managed company, decisions can be made very quickly. Nevertheless, according to Kress, it is essential not to ignore the workforce but to seek their support. “The will to develop further has to come from management; but a large part of the workforce should support this decision,” says the expert. If you want to digitize, you have to “take the employees with you.” It’s not about involving all employees, “otherwise it’s like with the chefs”, too many spoil the broth. But you have to inform and educate them so that they can identify with the innovation.

The will of the management level to further develop the company is also decisive. The fact that in a family business the boss not only ” keeps up with the times at the age of 80″ and is even a step ahead, is not a matter of course. w.i.l.m.a. shows: The courage to change has paid off.

Convince with factual arguments

However, development did not go entirely smoothly. Although the workforce was on board and supported the change, there was external opposition, particularly from site foremen who feared ‘surveillance’. It took a lot of persuasion and discussion to get them on board, Kress explains. The fact that using w.i.l.m.a. saves time and in the end convinced even the biggest doubters. According to Kress, it is important to bring sensible arguments and be honest.

Now even those who initially expressed doubts are convinced. “There’s only positive feedback concerning the device,” says Kress happily. “It’s a lot of fun to work with. Instead of rummaging through slips of paper with handwritten notes, for which I first need a scribe in order to even understand what the good colleague wanted to say, with w.i.l.m.a. everything ist much faster and clearer.”

Parship in civil engineering

Choosing the right partner is essential for the development of new products. “We started with an electrician who handmade the controls – nice, but cumbersome,” says Kress. This was followed by cooperation with a company “who wrote us a controller – but there the reliability and availability were questionable, it was difficult to reach a contact person. It was a happy coincidence that we came together with eguana in 2017 and it fit so well – with the company, but also with the people.”

His tip for finding the right partner: “Observe the market to see if there is someone who is already going in the direction you are looking for. It may be that you find something at trade fairs and forums, but you can’t rely on that,” he advises instead to search the internet.

How to make the collaboration work

But it is not only the content that is decisive; reliability and trust are very important for good cooperation, as is open communication. “I spoke to Philipp at the time and he was of the same opinion: we speak openly. There was always two-way communication when someone wanted to know something.”

Although w.i.l.m.a. has long been in use by various customers, the project is never finished, since different users always inquire about special wishes. “One person would like something with a different deviation, the other would like to be able to enter additional information… DESOI is flexible here, and so is eguana.”

Obwohl w.i.l.m.a. längst bei verschiedenen Kunden im Einsatz ist, sei das Projekt dennoch niemals fertig, da immer unterschiedliche Anwender Anfragen stellen würden. „Der Eine möchte etwas in einer anderen Abweichung, der Andere möchte eine zusätzliche Information eingeben können, … DESOI ist hier flexibel und eguana auch.“ If a customer request is not feasible, this is also clearly communicated.

Kress is certain that not only w.i.l.m.a., but also special civil engineering will continue to develop. “Without tunnels and bridges (regardless of whether we move by horse-drawn carriage or car, with gas, fuel cells or electricity) there can be no infrastructure. More and more hast o be built.

*****

About Bernd Kress:

Bernd Kress, born in 1968, has been with DESOI for more than 33 years. Starting out as a mechanical engineer, he now works as a technical sales manager. Whether it is tunnel construction, cellar vaults or renovations of museums, the injection specialist has already seen a lot. To the digitization measures of DESOI GmbH he brings his broad range of experience – both from a technical and a human perspective.

From mechanics to electronics, from people to countries, there’s nothing that Kress doesn’t know. It is not without reason that when confronted with difficult situations eguana mechatronics engineer Peter Weihs often asks himself: “What would Bernd do in this situation?”